Case Study: Biochar as a Cement Replacement

December, 2024The feasibility of biochar as a cement replacement to reduce concrete’s carbon footprint

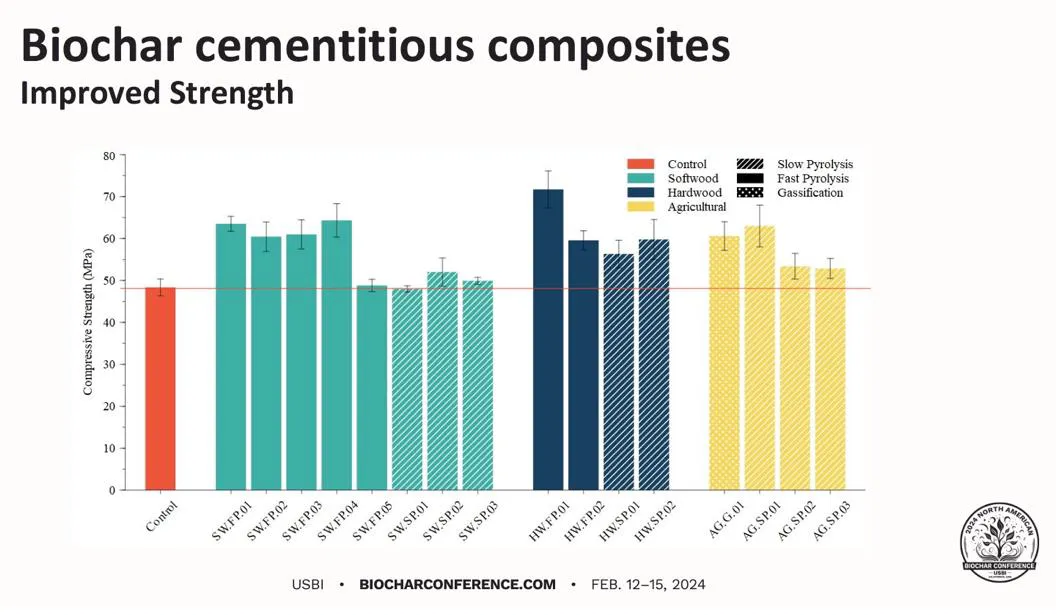

This study explores the feasibility of using biochar as a cement replacement to reduce the carbon footprint of concrete. Researchers tested 16 distinct biochars, replacing 10% of the cement weight, and found that biochar-cement mortars achieved similar or improved 28-day compressive strengths (≥ 50 MPa) compared to conventional concrete.

Key Findings:

- Biochar-cement mortars reached or exceeded the strength of traditional mortars at 28 days.

- Water permeability decreased with higher biochar content, suggesting improved durability.

- Biochar is compatible with fly ash as a cement replacement, accelerating strength gains when used together.

- Optimal biochar properties for cement replacement include high sorption capacity, low oxygen-to-carbon ratio (O/C), and high soluble silicon content.

Conclusion:

This study demonstrates that biochar can be successfully integrated into cementitious composites, producing a carbon-negative mortar that meets strength requirements. The findings suggest that biochar-cement mortars can be cost-competitive within the concrete industry, offering both mechanical benefits and significant reductions in carbon emissions.

Impact:

Biochar-cement mortars present a sustainable alternative to traditional concrete, reducing its environmental footprint without sacrificing performance. With proper processing and selection of biochar, this technology has the potential to revolutionize the concrete industry, promoting eco-friendly construction practices.

Source: Lori Tunstall, Ph. D.